Auloma is the main Italian manufacturer of servo press with pressing monitoring integrated for assembling press fit, metal forming and others industrial applications. In our range of products you can find servo presses for micro mechanic application until presses for heavy duties of 300 kN. All our devices could be equipped with our process monitoring system to analyse in run industrial processes such us : press fit, joining and crimping and more. Auloma devices can satisfy the exigences of many machine integrator and many industries. The high quality of our Servo Press Modules depend by many elements such as top level of components used, a robust and stiffness structure, an accurate force quality control, obtained by the use of precise force sensors. Skills and Knowledge makes Auloma Holding S.r.l a partner capable to offer advanced solutions in process monitoring devices applicable in many industrial fields to obtain a production with zero defects. All our devices are developed to provide the right benchmark to enhance your Six Sigma curve and to respect the ISO TS 16949. This is the new frontiers of industrial automation....

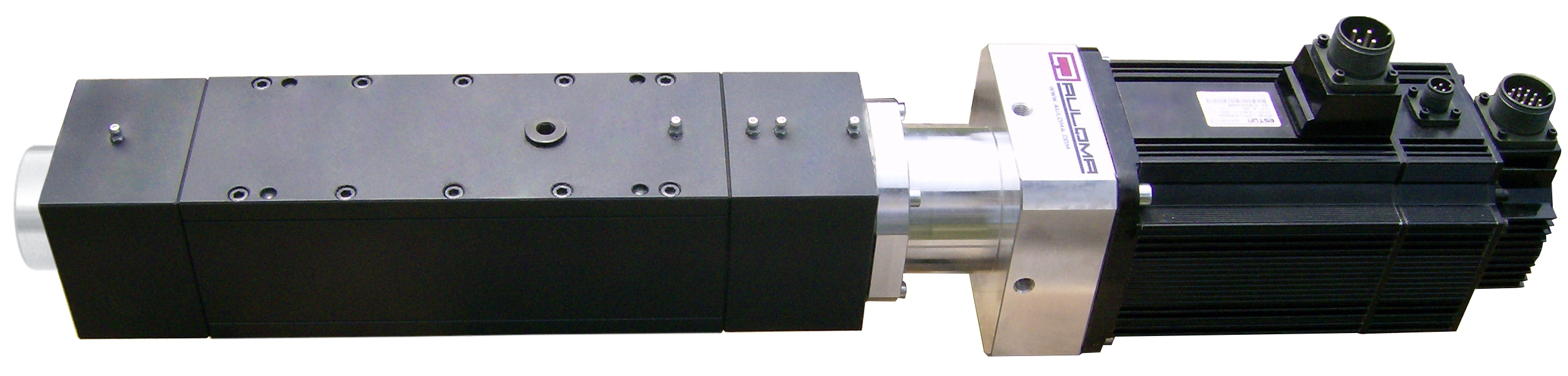

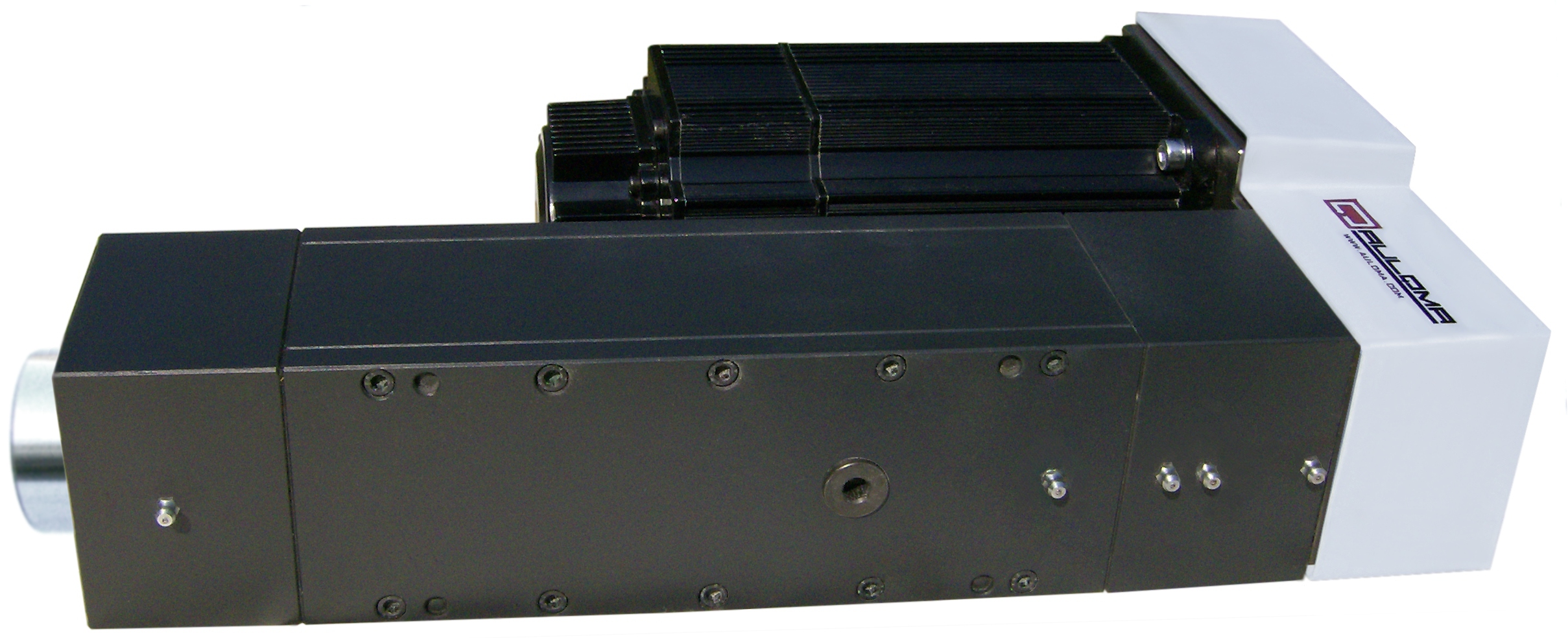

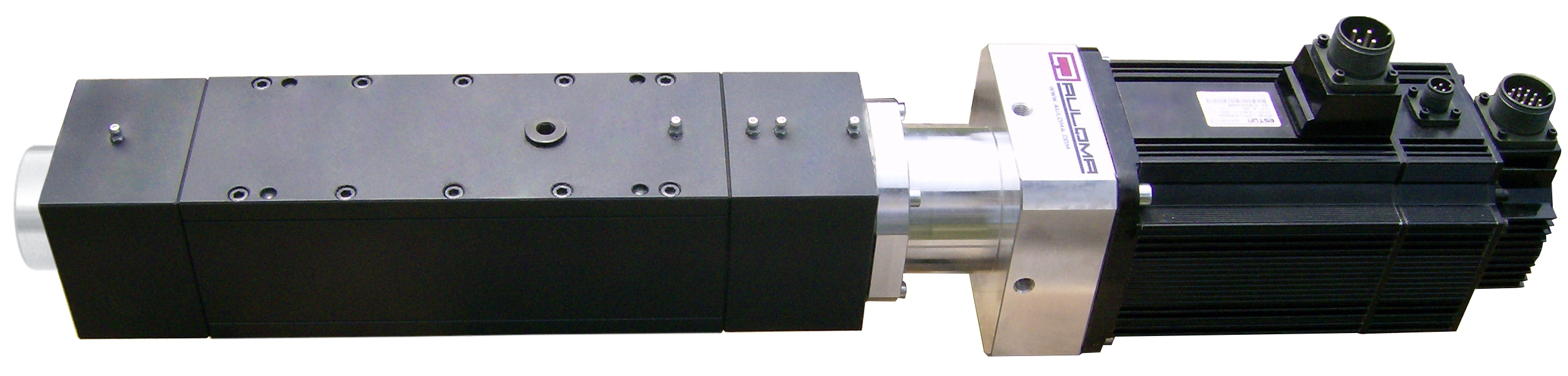

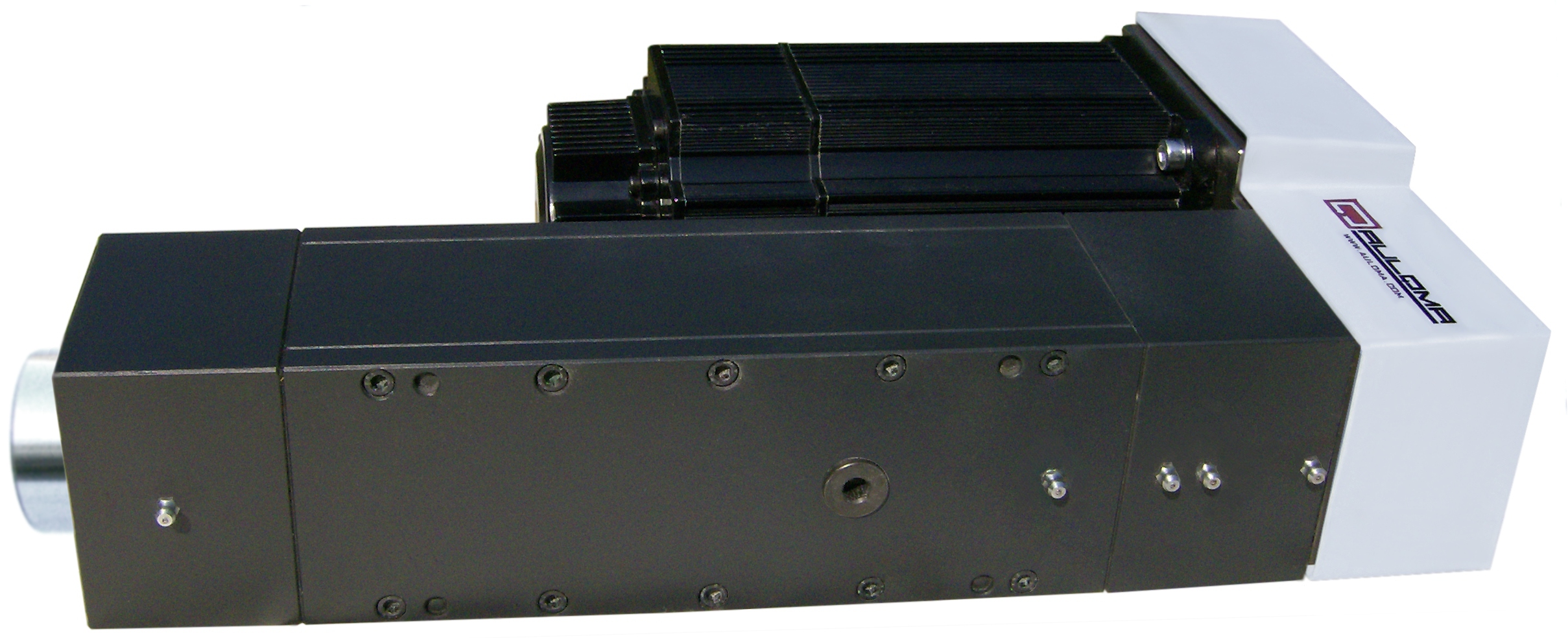

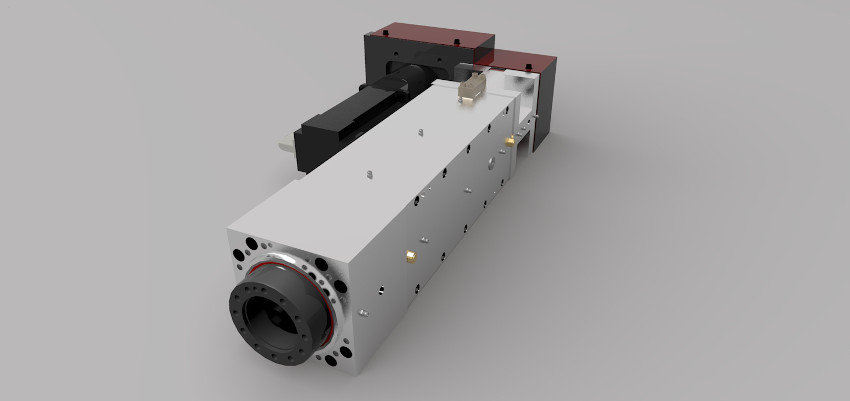

The servo press for high accuracy high accuracy in press fit The Auloma P512 servo press module include the compact design with the extreme stiffness. The device results an high precision screw spindle with ram position fully controlled by the CPU built-in installed in the servo drive. The servo press P512 is particularly suitable to monitoring the productive process and for seeking the minimal process variation such as parts defects and process abnormalities. The servo press mount a ground ball screw executed according the standard ISO T1,this extreme precision allow a repeatability of the ram lesser at 0.005 mm. Thanks to the extreme stiffness the dispersion of the force trough the structure elasticity is ward off and the measure of the two magnitudes Force and Displacement result reliable and precise. This precision allow at the process monitoring to have a very accurate signature of processed parts.

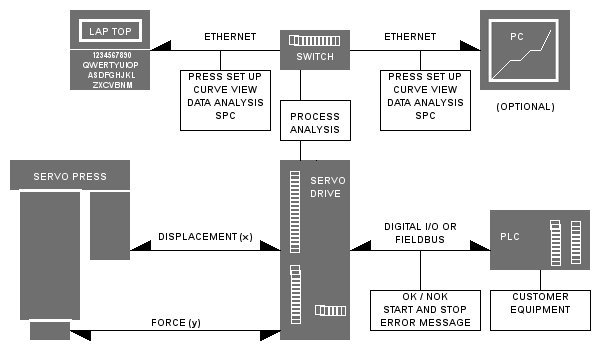

P512 servo presses are supported by the APM process monitoring to control in real time the press operations. The APM (Auloma Process Monitoring) is a software suite developed to program two different press environment:

Press Cycle

Process Analysis

The suit is very flexible and allow to develop whichever drive profile you want to control your process for:

and with a maximum of five break point or twohundred and fiftyfour in each recipe. The software APM is installed in the APM-PLC, a CPU with the firmware dedicated for the scope and supplied by Auloma in the servo drive. Through the Ethernet connection is possible connect whichever PC with the operative system MS Windows Vista® or later versions, where is installed our APM-PC ToolKit. In Few minutes, follow step by step the instructions is possible set-up the press drive profile and the relative force limits for set-up the process monitoring. In the APM-PLC can be stored only one recipes .The data gathered by APM from the servo presses are processed in real time and provide through the network of discrete I/O a feedback to the user's PLC about the analysis results, OK or NOK parts. through Etehernet TCP/IP network, the analysis data can be provided in CSV format to be analysed and stored in a hosted PC with our APM-PC Toolkit installed or with the almost MERP, ERP, Spread sheet available in the market. Thanks to the APM Auloma Process Monitoring your productive press process will be controlled in run and parts defects or process abnormalities will be sought in real time.

Visit Our Website www.auloma.com